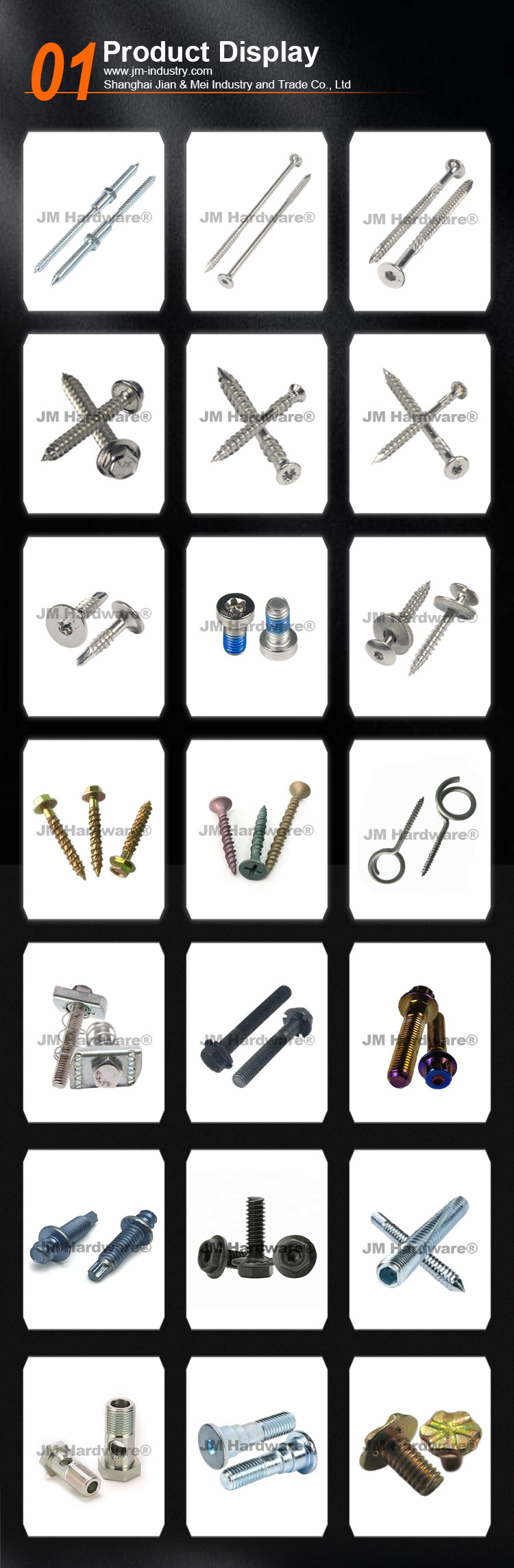

Custom Screw Manufacturers Prepared to Meet Your Ever Evolving Needs for Security Screws

Over the years, two things have stood true about security; it is never complete and it is never static. As one of the leading custom screw manufacturers in China., JM Hardware® provides design services for fasteners to meet just about any need. Customers rely on JM Hardware®'s professional screw manufacturing every day for custom designing and manufacturing of fasteners to meet their own unique objectives, size specifications, or to fit into some very unique positions. In response, our fastener and screw manufacturer at JM Hardware® has successfully developed a wide variety of custom products for just about every challenge they’ve faced. So if you can’t find the types of screws that fit your needs, let our manufacturers at JM Hardware® design custom screws for you.

JM Hardware® is capable of producing screws to many different standard and nonstandard sizes. Diameter ranges from #4(2.8)-1/2", and Length from 10-180mm(3/8”-7”). We have high competency in supplying a series of Head styles, including hex , flat, pan, truss, round, hex washer, Oval, pan framing, bugle,

fillister.And Drive styles, including Phil, slotted, Phil & slotted combination, hex socket etc.. A plethora of standard materials(Carbon Steel, Stainless Steel, Brass) is available for each, as well as high-strength engineered materials such as Monel Inconel, Hastelloy, and Titanium. Many protective and anti-corrosion coatings and treatments may be added, including brass, chrome, galvanization, nickel, composite, and specialty layers.

Types of screw grooves:

-

Threaded: This is the most common type of screw groove, where the helical ridges on the screw shaft are uniformly spaced and create a threaded pattern.

-

Square: Square grooves are found on square-headed screws and are designed to provide a secure grip for a wrench or pliers.

-

Phillips: Phillips grooves are cross-shaped and are designed to be used with a Phillips screwdriver. They are common in consumer electronics, appliances, and automotive applications.

-

Torx: Torx grooves have a six-pointed star shape and are designed to be used with a Torx screwdriver. They are commonly used in automotive and computer applications.

-

Pozidriv: Pozidriv grooves are similar to Phillips grooves but have additional cross-shaped ridges. They are commonly used in construction and woodworking applications.

-

Slotted: Slotted grooves are simple linear grooves that are designed to be used with a flathead screwdriver. They are commonly used in furniture and cabinetry applications.

-

Hex: Hex grooves are found on hex-headed screws and are designed to be used with a hex wrench or socket. They are commonly used in construction and automotive applications.

-

Tri-wing: Tri-wing grooves have three wings or lobes and are commonly used in electronics and aerospace applications.

-

Security: Security grooves are designed to prevent tampering and require a special tool toinstall or remove the screw. They are commonly used in high-security applications, such as in prisons, airports, and government facilities.

-

One-way: One-way grooves are designed to be installed with a standard tool but cannot be removed with the same tool. They are commonly used in public places, such as restrooms, to prevent vandalism.

-

Double-start: Double-start grooves have two threads that start at the same point on the screw shaft and are commonly used in lead screws and other power transmission applications.

-

Acme: Acme grooves are trapezoidal in shape and are commonly used in power transmission applications, such as in lead screws and jackscrews.

-

Buttress: Buttress grooves have one thread with a flat surface and one with an angled surface, and are commonly used in applications where high axial loads are required.

-

Knurled: Knurled grooves have a textured surface that provides a secure grip and are commonly used in applications where the screw needs to be tightened by hand, such as in knobs and handles.

These are just a few examples of the many types of screw grooves that exist, each designed for specific applications and use cases.

JM Hardware® can customize Groove types according to your requirements, you can send your specific requirements to our email: xarella.huang@jm-industry.com

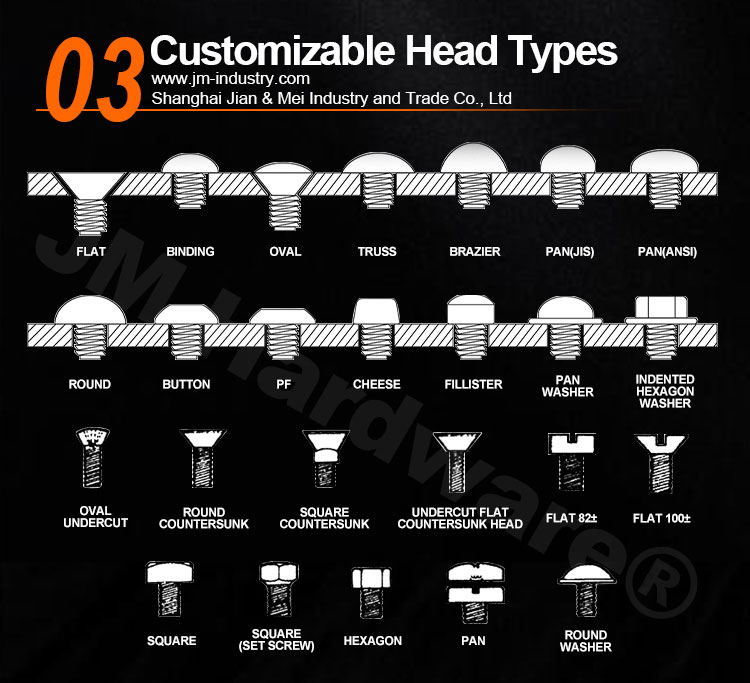

Types of screw Head:

-

Flathead: Flathead screws have a flat top surface with a single slot for a screwdriver. They are commonly used in woodworking and furniture applications.

-

Phillips: Phillips screws have a cross-shaped recess and are designed to be used with a Phillips screwdriver. They are commonly used in electronics, appliances, and automotive applications.

-

Hex: Hex screws have a hexagonal head and are designed to be used with a hex wrench or socket. They are commonly used in construction and automotive applications.

-

Torx: Torx screws have a six-pointed star shape and are designed to be used with a Torx screwdriver. They are commonly used in automotive and computer applications.

-

Square: Square screws have a square-shaped head and are designed to be used with a square wrench or pliers. They are commonly used in construction and woodworking applications.

-

Button: Button screws have a low-profile dome-shaped head and are commonly used in electronics and computer applications.

-

Pan: Pan screws have a slightly rounded top surface and are commonly used in electronics and automotive applications.

-

Round: Round screws have a circular head and are commonly used in decorative applications.

-

Truss: Truss screws have a low-profile rounded head and are commonly used in furniture and cabinetry applications.

-

Oval: Oval screws have an oval-shaped head and are commonly used in decorative applications.

-

Mushroom: Mushroom screws have arounded head with a slightly larger diameter than the screw shaft and are commonly used in furniture and cabinetry applications.

-

Cheese: Cheese screws have a cylindrical head with a slightly tapered top and are commonly used in electronics and automotive applications.

-

Fillister: Fillister screws have a cylindrical head with a slightly concave top and are commonly used in engine and machinery applications.

-

Binding: Binding screws have a cylindrical head with a slightly raised rim and are commonly used in bookbinding and leatherworking applications.

-

Socket: Socket screws have a recessed hexagonal socket in the head and are designed to be used with a hex wrench or socket. They are commonly used in machinery and automotive applications.

-

Security: Security screws have a unique head design that requires a special tool to install or remove the screw. They are commonly used in high-security applications, such as in prisons, airports, and government facilities.

-

One-way: One-way screws have a head that can be installed with a standard tool but cannot be removed with the same tool. They are commonly used in public places, such as restrooms, to prevent vandalism.

These are just a few examples of the many types of screw heads that exist, each designed for specific applications and use cases.

JM Hardware® can customize Head types according to your requirements, you can send your specific requirements to our email: xarella.huang@jm-industry.com

Types of screw tip:

-

Flat: Flat tips are the most common type of screw tip and have a flat surface that is designed to fit into a slotted screw head.

-

Phillips: Phillips tips have a cross-shaped design that is designed to fit into a Phillips screw head.

-

Pozidriv: Pozidriv tips have a cross-shaped design that is similar to Phillips tips but with additional cross-shaped ridges. They are commonly used in construction and woodworking applications.

-

Torx: Torx tips have a six-pointed star shape that is designed to fit into a Torx screw head. They are commonly used in automotive and computer applications.

-

Hex: Hex tips have a hexagonal shape that is designed to fit into a hex screw head. They are commonly used in construction and automotive applications.

-

Robertson: Robertson tips have a square-shaped design that is similar to a Phillips tip but with a square-shaped recess. They are commonly used in construction and woodworking applications.

-

Tri-wing: Tri-wing tips have three wings or lobes and are commonly used in electronics and aerospace applications.

-

Spanner: Spanner tips have two notches that are designed to fit into a spanner screw head. They are commonly used in security applications.

-

Clutch: Clutch tips have a circular design with a single slot that is designed to fit into a clutch screw head. They are commonly used in electronics and automotive applications.

-

One-way: One-way tips have a design that allows them to be installed with a standard tool but cannot be removed with the same tool. They are commonly used in public places, such as restrooms, to prevent vandalism.

-

Tri-lobular: Tri-lobular tips have three lobes that are designed to fit into a tri-lobular screw head. They are commonly used in automotive and electronics applications.

-

Pin-in-hex: Pin-in-hex tips have a hexagonal shape with a small pin in the center that is designed to fit into a pin-in-hex screw head. They are commonly used in high-security applications.

-

ACR: ACR tips have a design that is similar to a Phillips tip but with a smaller point and additional cross-shaped ridges. They are commonly used in construction and woodworking applications.

-

Hi-Torque: Hi-Torque tips have a design that is similar to a Phillips tip but with a larger point and additional cross-shaped ridges. They are commonly used in construction and automotive applications.

These are just a few examples of the many types of screw tips that exist, each designed for specific applications and use cases.

JM Hardware® can customize Tip types according to your requirements, you can send your specific requirements to our email: xarella.huang@jm-industry.com

Types of screw surface:

-

Plain: Plain screws have a smooth surface without any additional coatings or treatments.

-

Zinc-plated: Zinc-plated screws have a thin layer of zinc coating on the surface, which provides some protection against corrosion.

-

Black oxide: Black oxide screws have a dark, matte black finish that is created through a chemical process. This finish provides some protection against corrosion and wear.

-

Galvanized: Galvanized screws have a layer of zinc coating that is applied through a hot-dip process. This provides a high level of protection against corrosion.

-

Nickel-plated: Nickel-plated screws have a layer of nickel coating on the surface, which provides some protection against corrosion and wear.

-

Chrome-plated: Chrome-plated screws have a layer of chrome coating on the surface, which provides a high level of protection against corrosion and wear. This finish is commonly used in automotive and decorative applications.

-

Powder-coated: Powder-coated screws have a layer of dry powder coating that is applied electrostatically and then cured under heat. This provides a durable and long-lasting finish that is resistant to corrosion and wear.

-

Anodized: Anodized screws have a layer of oxide coating that is created through an electrochemical process. This provides a hard, durable, and corrosion-resistant finish that is commonly used in aerospace and military applications.

-

Ceramic-coated: Ceramic-coated screws have a layer of ceramiccoating on the surface, which provides a high level of protection against wear and corrosion. This finish is commonly used in high-stress and high-temperature applications.

-

Teflon-coated: Teflon-coated screws have a layer of Teflon or similar fluoropolymer coating on the surface, which provides a non-stick, low-friction surface that is resistant to corrosion and wear. This finish is commonly used in food processing and medical applications.

-

Phosphate-coated: Phosphate-coated screws have a layer of phosphate coating that is applied through a chemical process. This provides a durable and corrosion-resistant finish that is commonly used in automotive and machinery applications.

-

E-coated: E-coated screws have a layer of electro-deposited coating that is applied through an electrostatic process. This provides a durable and long-lasting finish that is resistant to corrosion and wear.

These are just a few examples of the many types of screw surfaces that exist, each designed for specific applications and use cases.

JM Hardware® can customize Head types according to your requirements, you can send your specific requirements to our email: xarella.huang@jm-industry.com

Types of screw material:

-

Steel: Steel screws are the most common type and are available in various grades and alloys. They are strong, durable, and resistant to wear and corrosion.

-

Stainless steel: Stainless steel screws have a higher level of corrosion resistance than regular steel screws. They are commonly used in applications where exposure to moisture or chemicals is a concern.

-

Aluminum: Aluminum screws are lightweight and corrosion-resistant. They are commonly used in applications where weight is a concern, such as in aerospace and automotive applications.

-

Brass: Brass screws have a gold-like appearance and are corrosion-resistant. They are commonly used in decorative and electrical applications.

-

Copper: Copper screws have excellent electrical conductivity and are commonly used in electrical and plumbing applications.

-

Titanium: Titanium screws are strong, lightweight, and corrosion-resistant. They are commonly used in aerospace, medical, and high-performance applications.

-

Inconel: Inconel screws are a family of high-performance alloys that are strong, heat-resistant, and corrosion-resistant. They are commonly used in aerospace, nuclear, and chemical processing applications.

-

Monel: Monel screws are a family of alloys that are strong, corrosion-resistant, and have excellent mechanical properties. They are commonly used in marine, chemical processing, and oil and gas applications.

-

Nylon: Nylon screws are lightweight, non-corrosive, and have good insulation properties. They are commonly used in electrical and electronic applications.

-

Plastics: Plastic screws are available in various materials, such as nylon, PVC, and polycarbonate. They are lightweight, non-corrosive, and have good insulation properties. They are commonly used in electrical, medical, and automotive applications.

-

Carbon fiber: Carbon fiber screws are lightweight and have high strength-to-weight ratios. They are commonly used in aerospace, automotive, and sports equipment applications.

-

Ceramic: Ceramic screws have high strength and are resistant to wear and corrosion. They are commonly used in high-temperature and chemical processing applications.

-

Bronze: Bronze screws have good corrosion resistance and are commonly used in marine and electrical applications.

-

Zinc: Zinc screws have good corrosion resistance and are commonly used in construction and outdoor applications.

These are just a few examples of the many types of screw materials that exist, each designed for specific applications and use cases.

JM Hardware® can customize material according to your requirements, you can send your specific requirements to our email: xarella.huang@jm-industry.com

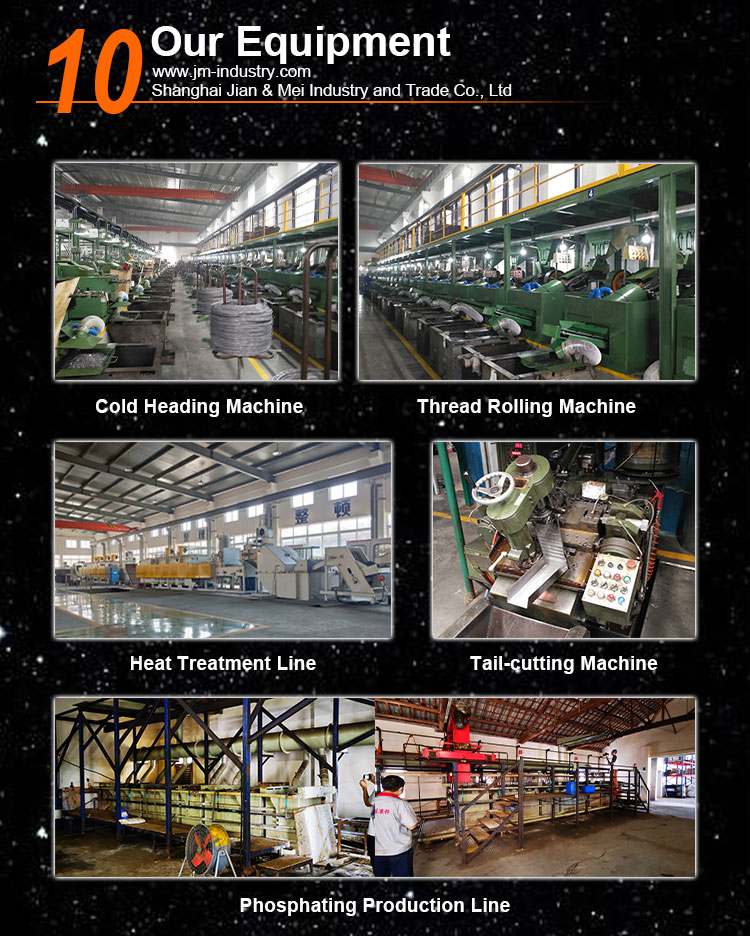

Our vision is to make JM Hardware® a well-known Chinese brand of high-end hardware parts in the world,and your cooperation will be an important part of it

If you do not see the product you need, or you have special customization requirements, you can send an email to xarella.huang@jm-industry.com. JM Hardware® will do our best to help you solve the problem