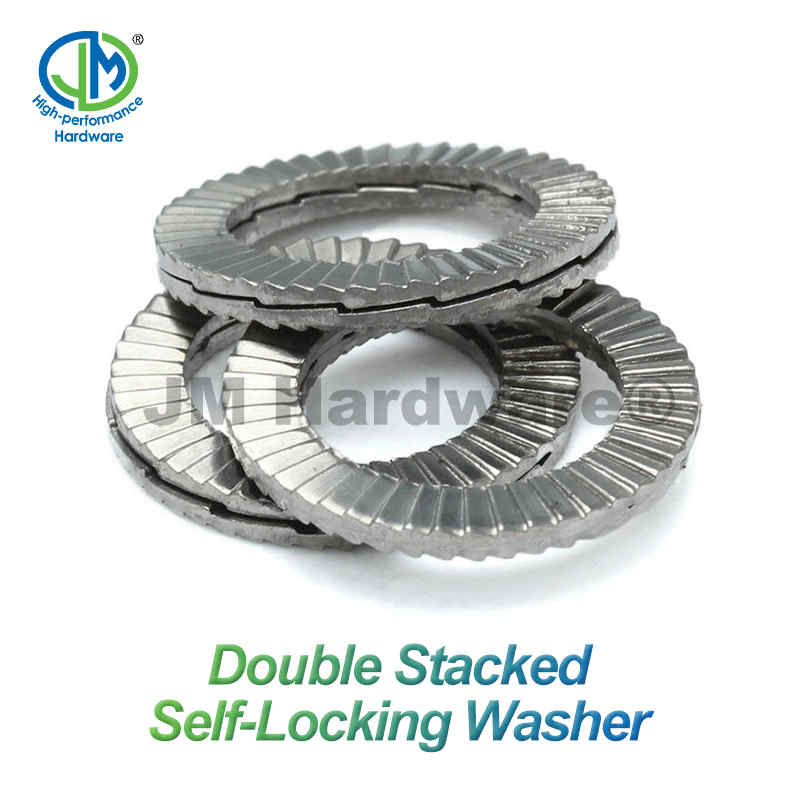

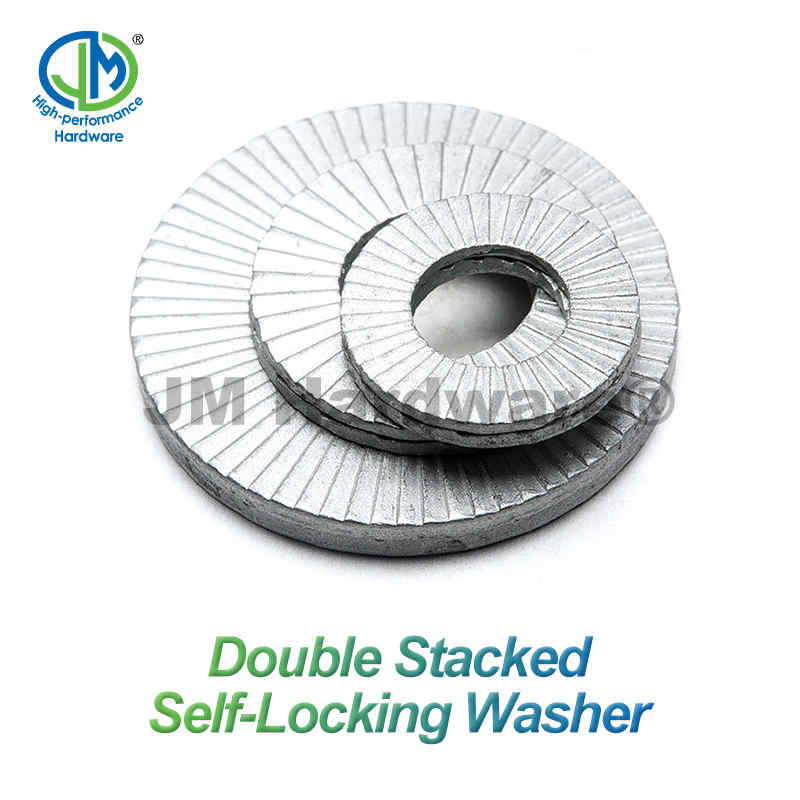

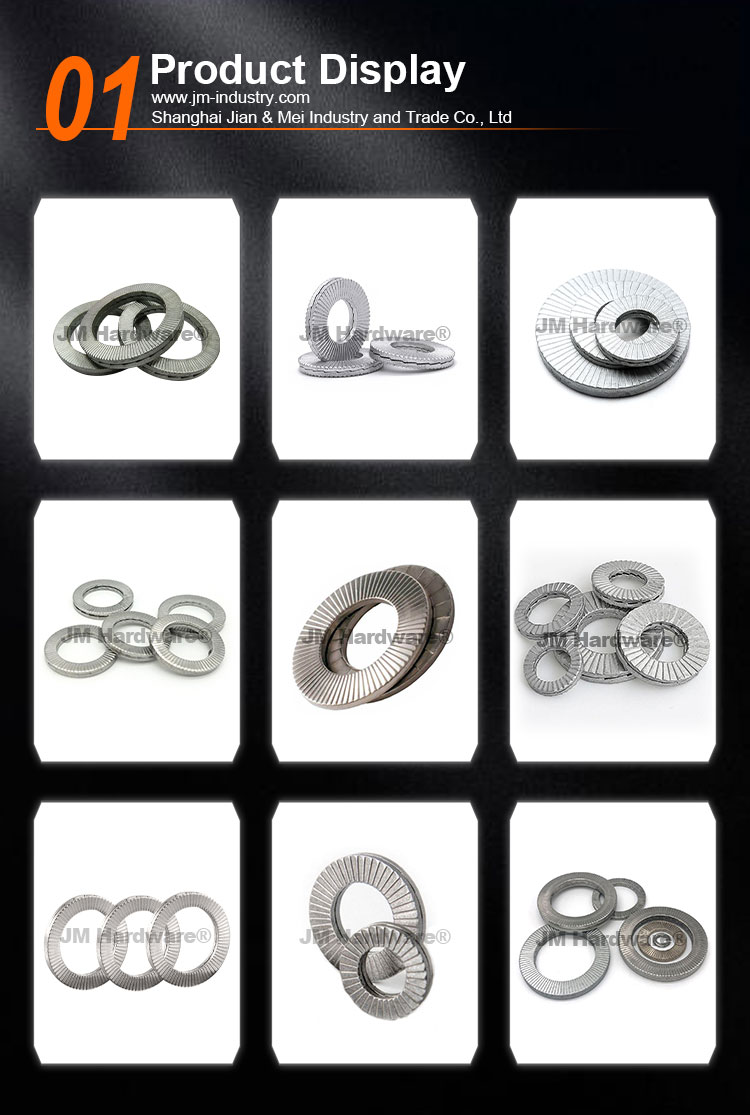

JM Hardware® Wedge lock washer DIN25201/ Double Stacked Self-Locking Washer

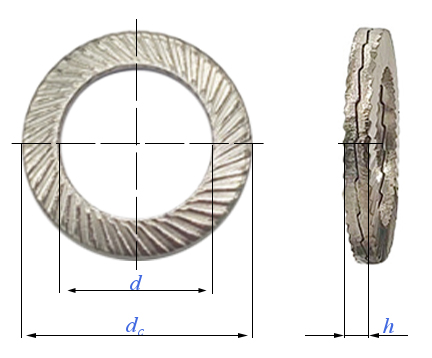

The locking washers are supplied and installed in pairs - cam face to cam face. When the bolt/nut is tightened, the teeth grip and seat onto the mating surfaces. The washers lock in place, allowing movement only across the face of the cams. Any tendency for the bolt/nut to loosen is blocked by the wedge effect of the cams. This positively locks the fastener even when it is subjected to vibration or dynamic loads.

Nord-Lock Locking Washers have a high corrosion resistance and can be reused up to 5 times.

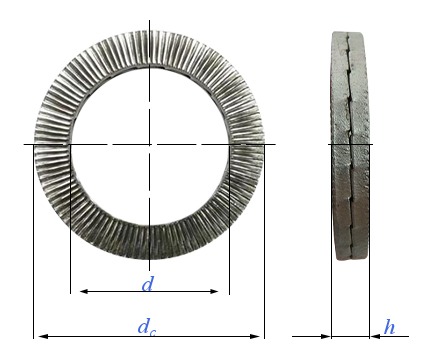

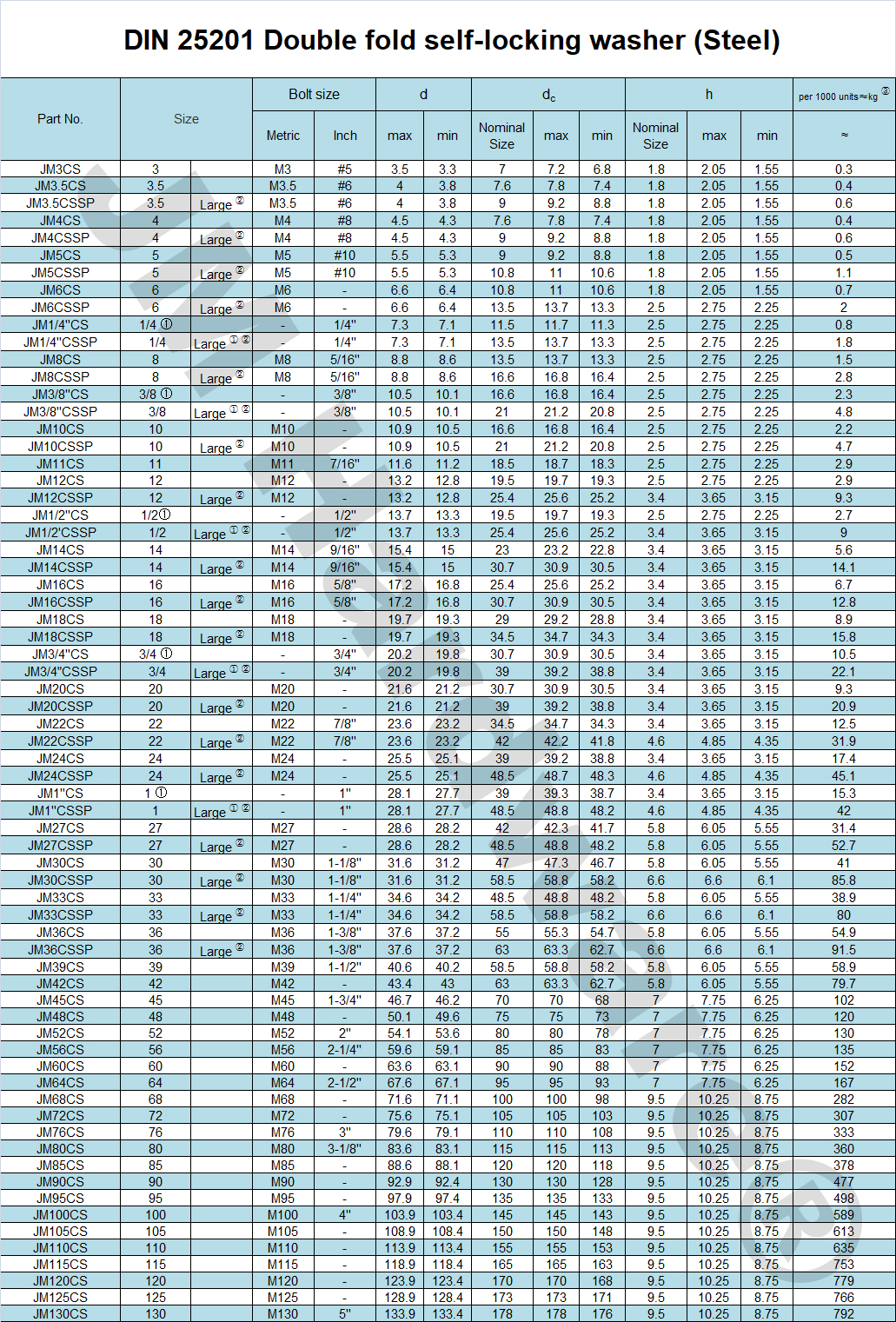

They are available in in thread sizes from M3 to M42 and diameters from 7mm to 63mm and they meet the DIN25201 standard.

Advantages:

• Resist loosening caused by vibration or movement

• Ease of assembly and disassembly

• Locking function is not lost by lubrication

• Positive locking at low and high preload levels

• Same temperature characteristics as standard bolt/nut

• Reusable up to 5 times

Typical applications:

Construction equipment, Automotive and Trucking industry, Agricultural equipment, Utilities, Manufacturing Equipment, Railroad equipment, Process industries

The principle of DIN25201 double-stack self-locking washers: the inclination angle α of the unique helical tooth surface inside the washer is greater than the inclination angle β of the bolt thread. During assembly, the inner helical tooth surfaces are opposite, and the friction coefficient of the outer radial convex surface (outer knurled tooth surface) of the washer is larger than that of the inner helical tooth surface, and it is in a state of engagement with the contact surfaces at both ends. When the connecting piece is vibrated and the bolt tends to loosen, only the helical teeth on the inside of the two washers are allowed to rise and move relative to each other to generate lifting tension. The unique tooth system utilizes tension to create a high resistance at the fastened connection to withstand vibrational forces, thus achieving 100% anti-loosening effect.

JM Hardware® Double-stacked self-locking lock washers are composed of two pieces in pairs, the outer side has radially inclined fine teeth, and the inner side has a radial wide tooth surface (washer) with a larger inclination angle. The angle of the wide tooth surface is greater than the angle of the bolt thread. When reassembling, the inner helical tooth surface is opposite, and the outer radial tooth surface is in a state of engagement with the contact surfaces at both ends. When the connecting piece is subject to vibration and the bolt tends to loosen, only two pieces are allowed. The relative displacement between the helical teeth on the inside of the washer generates a tension lift, thereby achieving 100% prevention of loosening.

Our vision is to make JM Hardware® a well-known Chinese brand of high-end hardware parts in the world,and your cooperation will be an important part of it

If you do not see the product you need, or you have special customization requirements, you can send an email to xarella.huang@jm-industry.com. JM Hardware® will do our best to help you solve the problem

①,The specification is in inches.

②,Large Type

③,“Thousands of pieces” can be understood as “the weight of each thousand sets of washers”

②,Large Type

③,“Thousands of pieces” can be understood as “the weight of each thousand sets of washers”

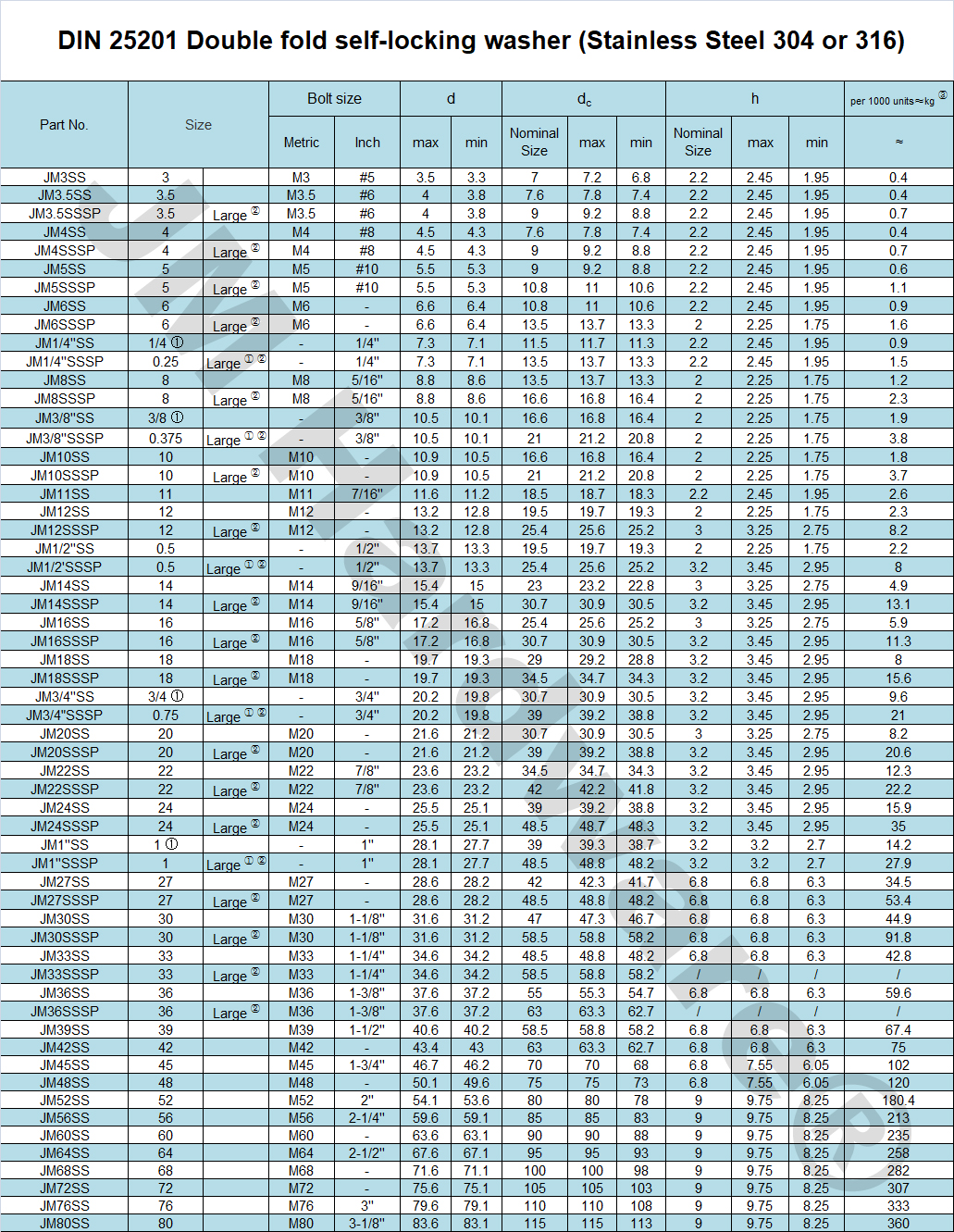

①,The specification is in inches.

②,Large Type

③,“Thousands of pieces” can be understood as “the weight of each thousand sets of washers”

when you send RFQ,please tell us what you need SS304 or SS316 (A2 or A4)

②,Large Type

③,“Thousands of pieces” can be understood as “the weight of each thousand sets of washers”

when you send RFQ,please tell us what you need SS304 or SS316 (A2 or A4)

Related Product

Standard Fastener